Elastopower helps industrial concerns to find the right solution for all surface waterproofing needs, to prevent water leaks from impairing output quality, the operation of equipment or workplace health conditions. The spray-on technology renders all previous waterproofing methods obsolete. It has shorter application times, is more durable and has much greater elasticity than any traditional technique.

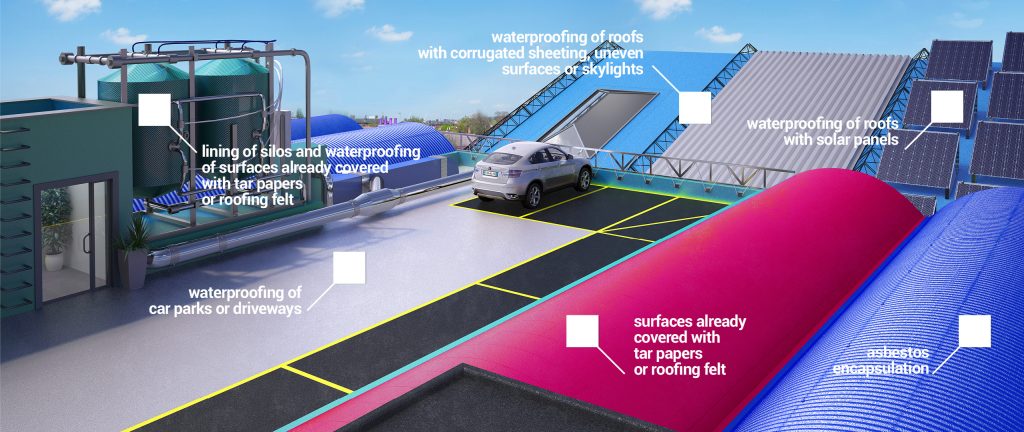

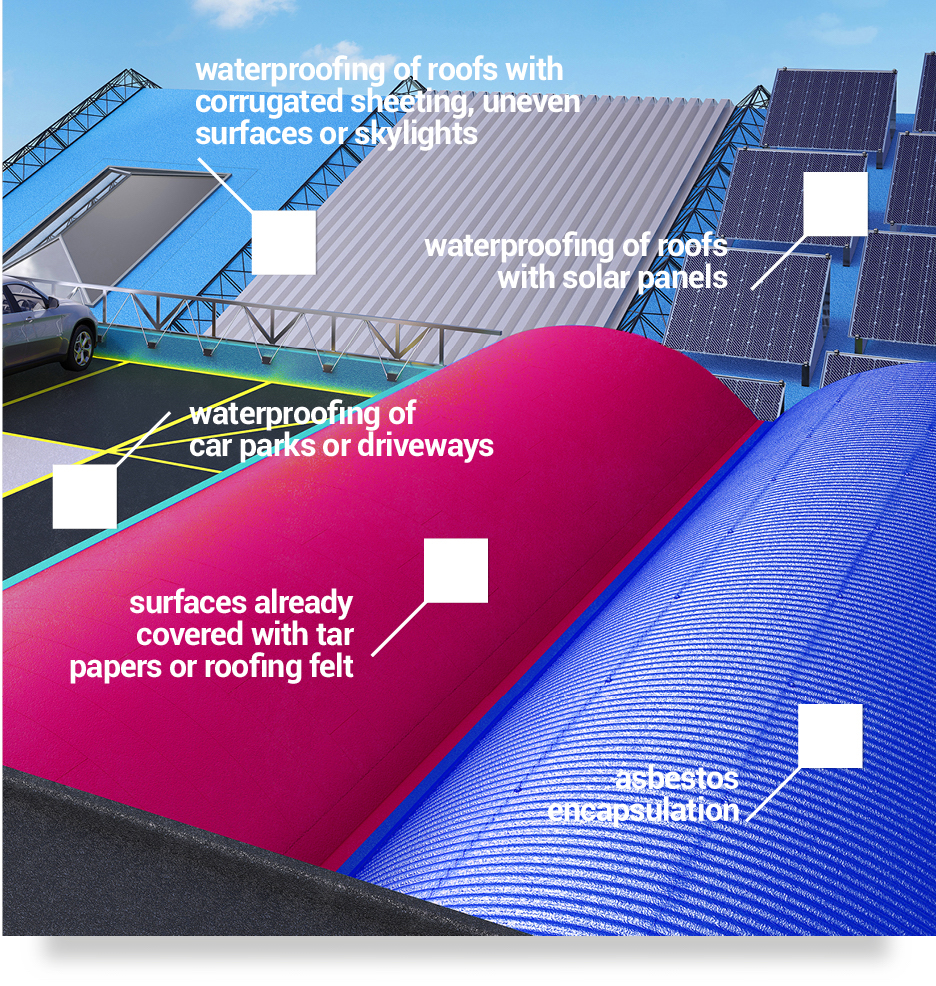

Elastopower solutions form a seamless waterproof coating on surfaces of any shape and size, horizontal or vertical and even with asymmetrical curves, overhangs, steps, recesses and hidden nooks and crannies and in any material, such as tar paper or roofing felt, sheet metal, wood, concrete, tiling, PVC, resins and asbestos

Elastopower provides an all-inclusive service from initial inspection to closure of the worksite. The benefits of our coating, effective immediately after application, enable:

non-invasive works with no demolition

seamless, joint-free coatings

fast setting

no increase in permanent structural load

high level of chemical and mechanical resistance

maintenance of high elasticity, up to 600%

resistance to weather and thermal shock

anti-slip, drive-over surface

food industry compliance

B ROOF(t4) certification conformity for photovoltaic systems

elimination of other maintenance costs

10-year warranty with insurance policy

vast range of colours available

We have undertaken many waterproofing projects on industrial roofs, pavings, car parks, bridges, silos, water supply systems, containment basins and asbestos encapsulation treatments. View some of our successful case studies.

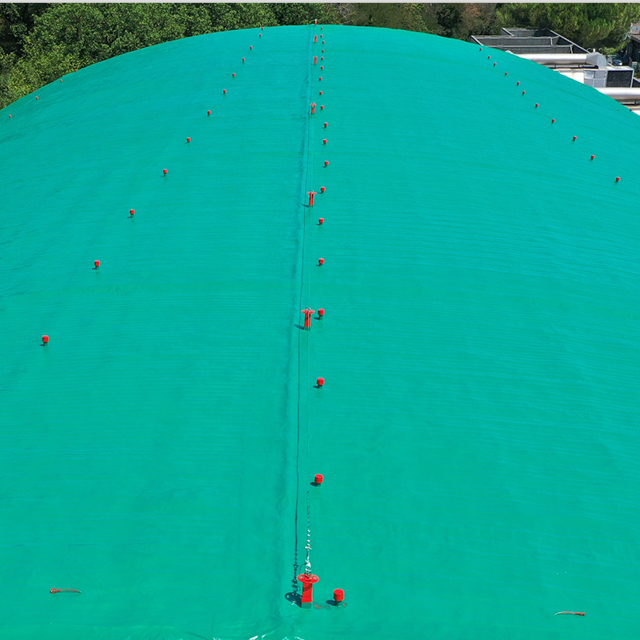

CURVED ROOF IN EXPANDED POLYURETHANE

7500 M2 _ SPORTS FACILITY

The curved sheet metal roof had serious water leak damage, with an expanded polyurethane layer destroyed by hail.

Preparation_ Installation of 150 breather vents to discharge the water vapour that had built up underneath the expanded polyurethane. Repair of the damaged surface with self-adhesive roofing felt to act as primer and aid perfect bonding of the coating, with no additional disposal or reconstruction costs.

Treatment_ ElastopowerM®. Rapid waterproofing treatment applied by spraying with high pressure bi-mixer pump systems.

Result_ New elastic, waterproof covering, ral 6037 colour, joint-free, drive-over, highly reflective, UV and fire-resistant, with B ROOF (t4) certification. The existing roof was repaired with a saving of 50%, without any additional maintenance costs

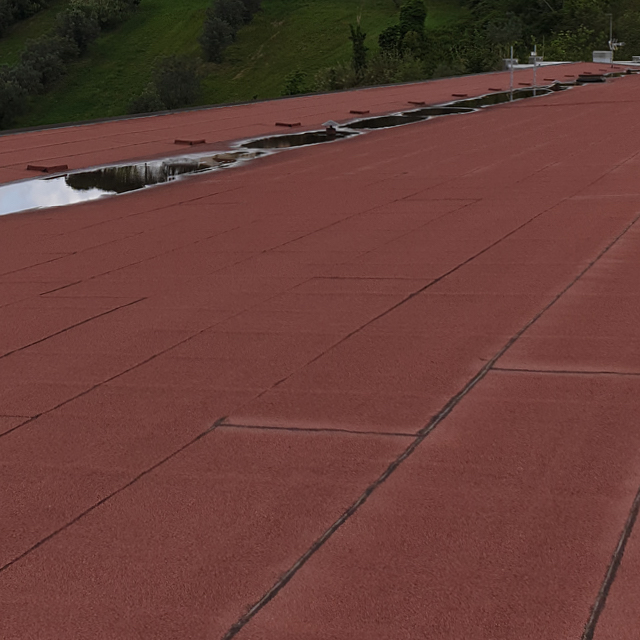

ROOFING FELT ROOF

3500 M2 _ STADIUM

The roofing felt roof had problems of water leaks and tars between the felt and the sheet metal surround. The customer requested urgent action to resolve the problem and to provide a colour match with the athletics track

Preparation_ Repair of the damaged roofing felt, cleaning of the surface, covering of the sheet metal with elastic tape, application of primer using rollers to allow sporting activities to continue uninterrupted and ensure perfect bonding of the coating.

Treatment_ ElastopowerG®. Rapid waterproofing treatment applied by spraying with high pressure bi-mixer pump systems.

Result_ New elastic, waterproof covering, ral 3003 colour, joint-free, drive-over, anti-slip, highly reflective, resistant to acids, oils, solvents, UV radiation and fire, with B ROOF (t4) certification.

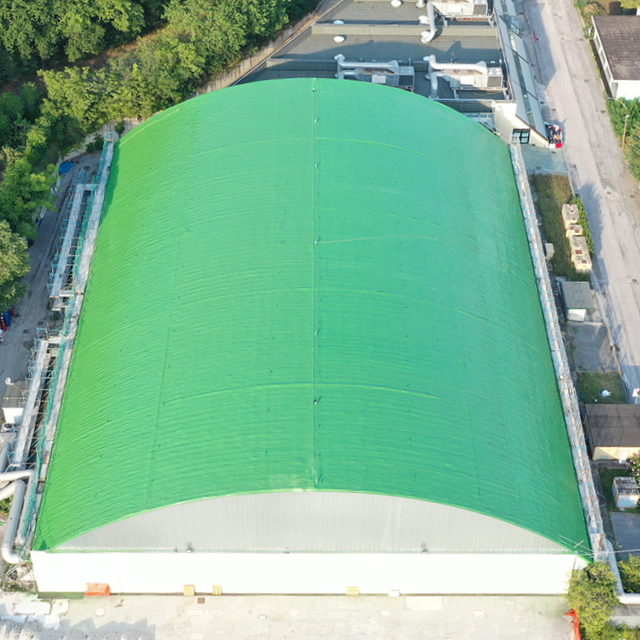

CURVED ROOF IN SHEET METAL

3500 M2 _ FACTORY

Water was leaking through the sheet metal roof, damaging raw materials and equipment. The customer wished to avoid demolition of the roof, so that production would not have to be stopped.

Preparation _ Washing with high pressure washer to clean the surface. Application of anti-corrosion primer for perfect bonding of the coating.

Treatment_ ElastopowerM®. Rapid waterproofing treatment applied by spraying with high pressure bi-mixer pump systems.

Result_ New elastic, waterproof covering, ral 9010 colour, joint-free, drive-over, anti-slip, highly reflective, resistant to chemicals, weather, UV radiation and fire, with B ROOF (t4) certification.

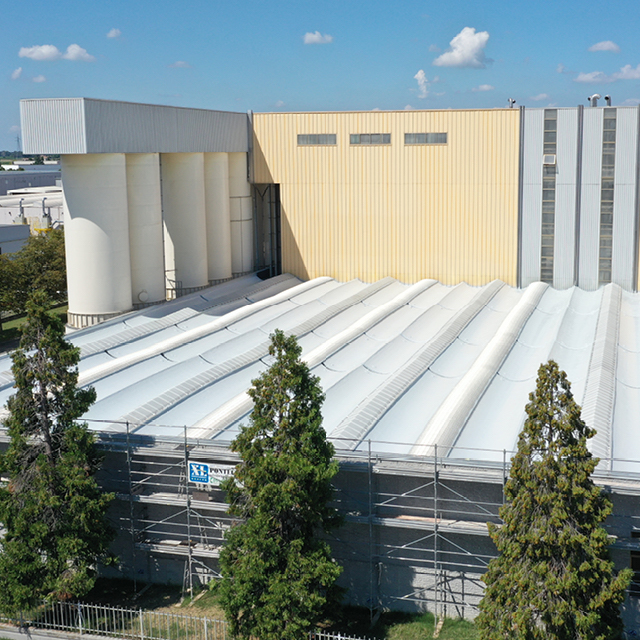

EXPANDED POLYURETHANE ROOF

5000 M2 _ FACTORY

Concrete roof in geometrical forms with expanded polyurethane insulation, with leaks from 90% of the surface. Work required in preparation for installation of an animal feed production line, to protect the roof against corrosion due to contact with feed dust and water.

Preparation _ Sandblasting, stripping of expanded polyurethane down to concrete substrate, restoration of gradients for rainwater run-off. Repair of skylights, application of primer for perfect bonding of the coating.

Treatment_ ElastopowerC®. Rapid waterproofing treatment applied by spraying with high pressure bi-mixer pump systems.

Result_ New elastic, waterproof roof covering, ral 7047 colour, joint-free, drive-over, anti-slip, highly reflective, resistant to chemicals, weather, UV radiation and fire, with B ROOF (t4) certification.

Information about other customised projects and treatments specifically for indoor or outdoor upgrades is available on request.